Research Paper代写参考:Automotive Spare Parts Manufacturing Supply Chain

Research Paper代写参考-汽车零部件制造供应链。本文是一篇留学生Research Paper写作范文,本研究旨在客观地研究全球供应链中的库存管理。本论文以汽车零部件制造行业的一家企业为例进行了案例研究,以了解全球供应链中与库存控制管理相关的重要职能方面。

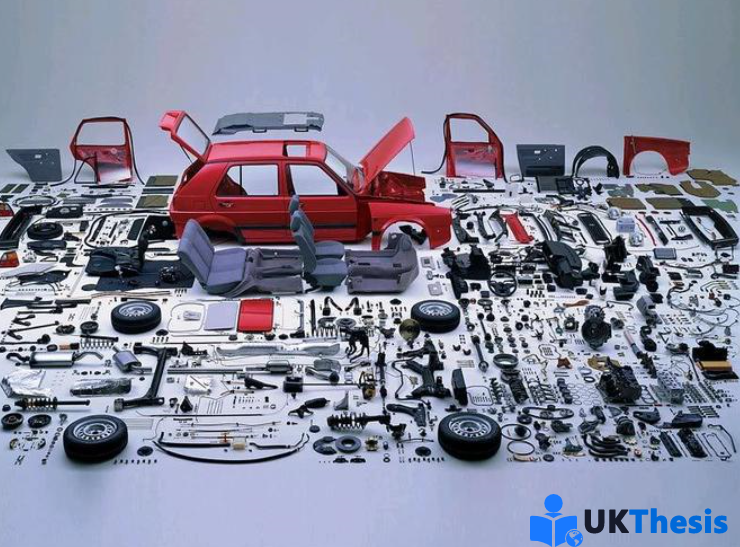

汽车行业一直是一个蓬勃发展的行业,在地方、国家和全球各个层面上都保持不变。汽车零部件的供应是汽车行业的一个重要环节和过程。许多中小企业通过库存管理有效地构成了全球供应链的一部分。下面就一起来看一下这篇关于汽车供应链方面的Research Paper范文的具体内容。

Abstract 摘要

This research study is objectively aimed at studying Inventory management in the global supply chain. The case study of an enterprise in the automotive spare parts manufacturing sector is presented to understand important aspects of functioning related to inventory control management in the global supply chain.

The automotive industry has always been a booming industry and continuous to remain the same on a all levels i.e. local, national and global. The supply of automotive components forms a vital link and process in the automotive industry. Many business small, medium-sized and large through inventory management form a part of the global supply chain effectively.

The researcher, proposes to present a case study analysis of Kapoor Automobiles (India), a medium-sized organization of repute and good market standing in the Global supply chain of automotive components. This research would throw light on the inventory management system employed by the organization, its effectiveness, shortcomings and remedial measures taken to fulfill consumer needs, retain them and grow through effective modes of Inventory control in the Global Supply Chain.

研究人员建议对卡普尔汽车(印度)进行案例分析,卡普尔汽车是一家在全球汽车零部件供应链中享有声誉和良好市场地位的中型组织。这项研究将揭示该组织采用的库存管理系统、其有效性、缺点以及为满足消费者需求而采取的补救措施,并通过全球供应链中的有效库存控制模式来保留和增长这些需求。

The researcher, further proposes to utilize business analytical tools of primary research i.e. qualitative research and quantitative research, secondary research, S.W.O.T analysis (Strength, weakness, opportunity and threats) and P.E.S.T.L.E. analysis (Political, economic, social, technological, legal and environmental) to ascertain the above mentioned objective of the research.

研究人员进一步建议利用初级研究的商业分析工具,即定性研究和定量研究、次级研究、S.W.O.T分析(优势、劣势、机遇和威胁)和P.e.S.T.L.e.分析(政治、经济、社会、技术、法律和环境),以确定上述研究目标。

Introduction:引言

Kapoor Automobiles (India) was incorporated in the year 1965 in Mumbai (India). In the commencement Kapoor Automobiles (India) functioning in the capacity of a trading company for the sale and purchase of automotive rubber parts. In the year 1990, the business enterprise ventured into manufacturing activities and gradually advanced towards gaining a secure and permanent market position overseas in the automotive rubber parts replacement segment of the market. Kapoor Automobiles (India) succeeded in doing so on account of the provision of high quality services to their growing clientele.

卡普尔汽车公司于1965年在印度孟买成立。开始时,卡普尔汽车以贸易公司的身份经营汽车橡胶零件的销售和采购。1990年,该企业开始从事制造活动,并逐步在汽车橡胶零件更换市场的海外市场取得稳固和永久的市场地位。卡普尔汽车之所以成功,是因为为其不断增长的客户提供了高质量的服务。

Kapoor Automobiles (India) places a high magnitude of emphasis on high quality and increased productivity to meet the global consumer demand and counter-attack competition. The Research and Development team of Kapoor Automobiles (India) focuses in continuity research on the changing consumer needs and the firm attempts to incorporate those needs in their production activities.

Kapoor Automobiles (India) has been recognized as an organization of international repute by the following certification:

ISO 9001: 2000 Quality Management System Certificate by French giants SGS.

卡普尔汽车高度重视高质量和提高生产力,以满足全球消费者需求和应对竞争。卡普尔汽车的研发团队专注于不断变化的消费者需求的连续性研究,并试图将这些需求纳入其生产活动。

卡普尔汽车公司通过以下认证被公认为具有国际声誉的组织:

法国巨头SGS颁发的ISO 9001:2000质量管理体系证书。

From humble beginnings of a small workshop, Kapoor Automobiles (India) currently has a manufacturing plant with an area of 12000 sq meters with state-of-the-art anti vibration connection technology. Here, assembly elements of rubber-metal composition are manufactured.

卡普尔汽车公司最初是一家小型车间,目前拥有一家占地12000平方米的制造工厂,采用最先进的防振连接技术。制造橡胶金属组合物的组装元件。

The highlighting aspects of Kapoor Automobiles (India) are as follows: 卡普尔汽车(印度)的突出方面如下

The organization has a staff of 127 production staff, 12 administrative officials and 2 rubber technicians.

The products of the organization are a varied range of automotive rubber components for vehicles such as Bedford, BMC, BMW, Fiat, Hino, Isuzu, Iveco, Lada, Land Rover, Mazda, Mercedes, Mitsubishi, Nissan, Opel, Peugeot, Renault Toyota, VW, Volvo to name a few for the purpose of exemplification.

该组织有127名生产人员、12名行政官员和2名橡胶技术人员。

该组织的产品是一系列汽车橡胶部件,用于贝德福德、BMC、宝马、菲亚特、日野、五十铃、依维柯、拉达、路虎、马自达、梅赛德斯、三菱、日产、欧宝、标致、雷诺丰田、大众、沃尔沃等汽车。

Kapoor Automobiles (India) focuses on four major production processes: 卡普尔汽车专注于四大生产流程

Rubber mixture preparation and Preforming 橡胶混合物制备和预成型

Metal forming and Machining 金属成形和加工

Metal and pipe surface preparation.金属和管道表面处理

Vulcanization 硫化

Kapoor Automobiles (India) has a clientele spread across the African and European continent and the Middle East. 卡普尔汽车的客户遍布非洲、欧洲大陆和中东。

Aims and Motivations of the Research Study:研究的目的和动机

The automobile industry is a global industry which is witnessing a high level of growth. The competition in this global industry necessitates a well-coordinated process of supply of the automotive parts to car manufacturers as an when there is a demand for the same. Thereby the need to have good level of inventory management in the global supply chain is of prime importance to meet the demand of the market, help the business to survive and grow in this competitive market.

汽车行业是一个全球行业,正在经历高水平的增长。这一全球行业的竞争需要一个协调一致的汽车零部件供应过程,以满足汽车制造商的需求。因此,在全球供应链中拥有良好的库存管理水平对于满足市场需求、帮助企业在竞争激烈的市场中生存和发展至关重要。

My motivation and aim of this research study is to comprehend all the aspects which make possible successful inventory control in global supply chain management. My area of research and analysis in this context would lay focus on the automotive parts manufacturing sector.

我这项研究的动机和目的是了解在全球供应链管理中实现成功库存控制的所有方面。我在这方面的研究和分析领域将侧重于汽车零部件制造业。

General Objectives:总体目标

This study aims at on a general or basic level understanding Global Supply Chain Management and its significance in today day and age of excessive competition. The objective is also to learn about all the factors which influence inventory control in global supply chain management in a positive and negative way especially the automotive spare parts industry. To gain knowledge about how an improvement in the smooth functioning of global supply chain management can be brought about by a good level of inventory control.

本研究旨在从总体上或基本上了解全球供应链管理及其在当今过度竞争时代的意义。目的还在于了解全球供应链管理中影响库存控制的所有因素,尤其是汽车零部件行业。了解如何通过良好的库存控制来改善全球供应链管理的顺利运作。

Specific Aims:具体目标

This research is specifically aimed at understanding the functions of Kapoor Automobiles (India) with regard to inventory control in global supply chain management. In this regard its current activities, the positive aspects, the shortcomings and how improvisation could be brought about in the process of inventory control of Kapoor Automobiles (India) for global supply chain management.

本研究旨在了解卡普尔汽车在全球供应链管理中的库存控制功能。在这方面,其当前的活动、积极方面、缺点以及如何在卡普尔汽车(印度)的库存控制过程中为全球供应链管理带来即兴发挥。

Research Questions:研究问题

This dissertation is aimed at answering the following questions: 本文旨在回答以下问题

What is Global Chain Supply Management?什么是全球供应链管理?

What is inventory control?什么是库存控制?

How does Inventory Control in Global Supply Chain Management function in context to the automotive spare parts industry?全球供应链管理中的库存控制如何在汽车零部件行业中发挥作用?

How do firms in the automotive spare parts industry effective manage inventory control as a part of Global Supply Chain Management?作为全球供应链管理的一部分,汽车零部件行业的企业如何有效地管理库存控制?

Kapoor Automobiles (India)’s strategy of Inventory Control in Global Supply Chain Management?卡普尔汽车在全球供应链管理中的库存控制策略?

How could Kapoor Automobiles (India) improve on their Inventory Control in Global Supply Chain Management and compete better in the overseas market?卡普尔汽车如何在全球供应链管理中改善库存控制,并在海外市场更好地竞争?

What are the future trends perceived in the Automotive parts Inventory Control in Global Supply Chain Management?全球供应链管理中汽车零部件库存控制的未来趋势是什么?

Dissertation Structure:论文结构

The structure of this dissertation incorporates the following: Chapter 5 lays focus on the theoretical grounding for the research, reviewing a generous selection of literature on Supply Chain Management, Inventory control, all the aspect necessary to be taken into consideration for successful inventory control, the need of it and Global Supply Chain Management. Furthermore the literature review also brings forth the importance of good inventory control in the global supply chain management of the automotive parts industry.

本论文的结构包括以下内容:第5章着重于研究的理论基础,回顾了大量关于供应链管理、库存控制、成功库存控制所需考虑的所有方面、库存控制的需求和全球供应链管理的文献。此外,文献综述还提出了良好的库存控制在汽车零部件行业全球供应链管理中的重要性。

Chapter 6 introduces the method of study to be employed to analyze inventory control in global supply chain management of Kapoor Automobiles (India). Chapter 7 presents the study’s findings and discussion which are initially presented in diagrammatic form, then discussed. Chapter 8 will collate the main findings of the study to provide solid conclusions. The limitations are given, followed by an appraisal of the project’s main strengths and weakness. Recommendations for future research are also provided.

第6章介绍了用于分析卡普尔汽车全球供应链管理中库存控制的研究方法。第7章介绍了本研究的发现和讨论,最初以图表形式呈现,然后进行了讨论。第8章将整理研究的主要发现,以提供可靠的结论。给出了限制,然后对项目的主要优势和劣势进行了评估。还提供了未来研究的建议

Literature Review:文献综述

Supply Chain Management: 供应链管理

A Supply Chain Management activity could be understood as the management of materials, vital information and finances as they are channelized from a supplier to the manufacturers then to the wholesaler, retailer and finally the consumer. The activity of supply chain management comprises of skillful coordination and integration of the above aspects within organizations and among them. The final goal of an efficient supply chain management process is to bring about a reduction in stock with the basic ideology that products are available when needed. (Cooper, M.C., Lambert, D.M., & Pagh, J. (1997)

供应链管理活动可以理解为材料、重要信息和财务的管理,因为这些信息从供应商流向制造商,然后流向批发商、零售商,最后流向消费者。供应链管理的活动包括在组织内部和组织之间熟练地协调和整合上述方面。高效供应链管理流程的最终目标是减少库存,并遵循产品在需要时可用的基本理念。

Supply chain management flows can be divided into three main flows which are as follows: 供应链管理流程可分为以下三个主要流程

The product flow 产品流程

The information flow 信息流

The finances flow 资金流

The product flow constitutes the flow of products or commodities from a supplier to a consumer. The second aspect which is information flow comprises of transmission of orders and updates on status deliveries. The third aspect is the financial flow which comprises of terms of credit, payments, consignment and title ownership arrangements. Supply Chain Management of different organization differs depending on the size and nature of the organization and the product manufactured. An effective supply chain management ensures process of obtaining supplies and components, conversion of the same in to finished products and making supply of these products to the final consumer. Supply Chain Management is the management of all these aspects aptly without delays and at a low cost fulfilling the needs of the consumer in the process. (Haag, S., Cummings, M., McCubbrey, D., Pinsonneault, A., & Donovan, R. (2006)

产品流构成了从供应商到消费者的产品或商品流。第二个方面是信息流,包括订单的传输和状态交付的更新。第三个方面是资金流,包括信贷条款、付款、寄售和所有权安排。不同组织的供应链管理因组织的规模和性质以及生产的产品而异。有效的供应链管理确保了获得供应品和部件、将其转化为成品以及向最终消费者供应这些产品的过程。供应链管理是对所有这些方面的恰当管理,无延迟,以低成本满足过程中消费者的需求。

There are six key elements to a supply chain: (Ketchen Jr., G., & Hult, T.M. (2006) 供应链有六个关键要素

Production 生产

Supply 供应

Inventory 库存

Location 位置

Transportation, and 运输,以及

Information 信息

The following describes each of the elements: 以下描述了每个元素

1. Production 生产

The needs (Kouvelis, P.; Chambers, C.; Wang, H. (2006) and demands of the consumer is taken into account prior to production. Decisions regarding what to product, how to produce and how many units need to produced are taken. Furthermore, it is also decided upon whether to produce the whole product or certain parts should be outsourced. These vital decision regarding production activities should be made keeping in mind the volume of goods, the quality, capacity and the consumer wants and levels of satisfaction. Decision regarding operational activities should focus on equipment maintenance, scheduling and quality control.

在生产之前,考虑了消费者的需求。关于生产什么、如何生产以及需要生产多少个单元的决策都需要做出。此外,还决定是生产整个产品还是外包某些零件。做出这些关于生产活动的重要决定时,应考虑到商品的数量、质量、产能以及消费者的需求和满意度。有关运营活动的决策应侧重于设备维护、调度和质量控制。

2. Supply 供应

An organization (Larson, P.D. and Halldorsson, A. (2004), cannot produce all the components required for the manufacture of a product and the need to outsource parts arises. The organization should be cautious in the choice it makes of the supplier of components. The focus of the organization while engaging a supplier to supply components should be on quality, flexibility and the development of velocity and at the same time should maintain low costs. In summation, vital decision has to be taken to make the outsourcing partnership or activity a viable one for the manufacture and supply of the final product.

一个组织无法生产产品制造所需的所有部件,因此需要外包部件。组织在选择组件供应商时应谨慎。组织在聘请供应商供应部件时,应将重点放在质量、灵活性和发展速度上,同时应保持低成本。总之,必须做出重要的决定,使外包伙伴关系或活动成为最终产品制造和供应的可行伙伴。

3. Inventory 库存

Important decisions (Lavassani, M. K., Movahedi B., Kumar V. (2008) regarding how much should be stocked in the organization should be taken. A proper balance should be maintained as inventory holding is an important aspect of a good supply chain management process. The consumer demands should be met up without any supply delay and hence optimum level of inventory should be decided upon and place at strategic consumer points to serve the consumer as and when the demand for the product arises. Control policies must be checked upon to maintain right levels of supply at order and reorder points.

重要的决定关于组织中应储备多少。应保持适当的平衡,因为库存持有是良好供应链管理流程的一个重要方面。消费者的需求应该在没有任何供应延迟的情况下得到满足,因此应该确定最佳库存水平,并将其放置在战略消费者点,以便在产品需求出现时为消费者服务。必须检查控制策略,以在订购点和再订购点保持正确的供应水平。

4. Location 位置

Strategic decisions (Movahedi B., Kumar V. (2008) regarding location of the production plant, facilities of stocking and distribution should be made to ensure that the consumer avails the product when he demands without any delay. When the parts or components are light in weight and market driven, manufacturing units should be located near the final consumer. In heavy industries, sources of raw materials should be taken in consideration while deciding where the manufacturing plant should be located. Tax and tariff issues should be looked into while making strategic decisions.

就生产工厂的位置、库存和分销设施做出战略决策,以确保消费者在其要求时及时获得产品。当零件或组件重量轻且受市场驱动时,制造单位应位于最终用户附近。在重工业中,在决定制造厂的位置时,应考虑原材料的来源。在作出战略决策时,应研究税收和关税问题。

5. Transportation 运输

In context (Mentzer, J.T. et al. (2001) to fulfilling consumer demands, decisions related to transportation and inventory are quite closely connected. Utility of air transport is quick but expensive in comparison to water or road transport but makes the product available in a short span of time to the consumer. Water or road transport means being in possession of high levels of in-house stock to meet immediate consumer demands. Depending upon the demand the product generates, the cost of the product and the stock available decision relating to transportation should be made.

在满足消费者需求的背景下,与运输和库存相关的决策密切相关。与水上或公路运输相比,航空运输的使用速度快但成本高,但可在短时间内向消费者提供产品。水上或公路运输意味着拥有高水平的内部库存,以满足消费者的即时需求。根据产品产生的需求,应做出与运输相关的产品成本和可用库存决策。

6. Information 信息

A (Simchi-Levi D.,Kaminsky P., Simchi-levi E. (2007) supply chain management in order to be effective focuses on acquiring information for point of final consumption and connecting the information resources all through the entire chain to bring an effective flow. A good organization of information is required to bring in innovation in operation. Connecting computers through networks and having the information flow streamlined helps consolidate knowledge and helps in creating velocity for the products. Account management software, product configurators, enterprise resource planning systems, and global communications are important factors to be considered.

为了有效,供应链管理侧重于获取最终消费点的信息,并将整个供应链的信息资源连接起来,以实现有效的流动。需要一个良好的信息组织,以实现运营创新。通过网络连接计算机并简化信息流有助于巩固知识并有助于为产品创造速度。客户管理软件、产品配置器、企业资源规划系统和全球通信是需要考虑的重要因素。

Pragmatic Applications 应用

Today the market scenario (de Kok, A.G., S.C. Graves (Editors) 2003) demands fast delivery of goods. By high levels of stocking, many organizations try to fulfill this market demand. The organizations are at times unable to produce goods as and when the market demands and hence maintains high stocks. If processes are analyzed in the supply chain then the causes and solutions could be found to bring reduction in throughput time. Reducing the time in the chain of events right from the moment the consumer places to the order to the delivery for the same could help a company gain a competitive edge without the need to have large stocks.

今天的市场场景要求快速交货。通过高库存,许多组织试图满足市场需求。这些组织有时无法在市场需要时生产商品,因此保持高库存。如果对供应链中的流程进行分析,则可以找到原因和解决方案,从而缩短生产时间。缩短从消费者下单到交货的时间,可以帮助公司在不需要大量库存的情况下获得竞争优势。

Need for an effective Supply Chain Management: 需要有效的供应链管理

There is a high degree (Stock, J.R., D.M. Lambert. 2001) of competition in the business scenario today which demands that an organization in order to have a competitive advantage should utilize its resources to do what it is good at and indulge in outsourcing those processes that are not significant from an overall objective of the organization. SCM enable an organization to restructure its complete operation focusing on core competencies and outsourcing certain processes which would help the organization gain apt market positioning. Furthermore, is important to make the right decisions of partners, resources and manpower. The organization should understand which process or pattern could reduce wastages and raise levels of competence.

当今的商业场景中存在着高度的竞争,这要求一个组织为了获得竞争优势,应该利用其资源来做自己擅长的事情,并将那些对组织总体目标不重要的流程外包出去。供应链管理使组织能够以核心能力为重点重组其完整运营,并将某些流程外包,这将有助于组织获得适当的市场定位。此外,重要的是对合作伙伴、资源和人力做出正确的决定。组织应了解哪种流程或模式可以减少浪费并提高能力水平。

For the sake of exemplification, the Japanese (Coyle, J.J., E.J. Bardi, C.J. 2002) car industry manufactures small cars by capitalizing on its available resources. The Japanese car industry effectively utilizes supply chain management to maximize core competencies and create niche market positioning. Toyota Motor Corporation, a Japanese company, is stated to be the number one auto car maker overpowering Ford and General Motors of the United States.

为了举例说明,日本汽车工业利用其现有资源制造小型汽车。日本汽车行业有效地利用供应链管理来最大限度地提高核心竞争力并创造利基市场定位。据报道,日本丰田汽车公司是压倒美国福特和通用汽车的头号汽车制造商。

Value Advantage 价值优势

Supply Chain Management (Bowersox, D.J., D.J. Closs, M.B. Cooper. 2002) has made provision for business nowadays to not just have benefits of productivity alone but also on value advantage. Productivity advantage provides a lower cost profile and the value advantage gives the product an extra ‘plus’ over competitive offerings.Through maximizing added value there is cost reduction and more innovation can be brought to the product and process. Mass manufacturing offers productivity advantage and through mass customization, consumers are given the value advantage. For illustrative purposes, the Toyota Production System practiced in Toyota, evaluates (Ballou, R.H. 2003) its supply chain and determines what is value added activities and what is not value added activities.

供应链管理已经为当今的企业提供了条件,不仅要有生产力的好处,还要有价值优势。生产力优势提供了较低的成本,价值优势使产品比竞争产品具有额外的“优势”。通过最大化附加值,可以降低成本,并为产品和流程带来更多创新。大规模制造提供了生产力优势,通过大规模定制,消费者获得了价值优势。出于说明目的,丰田生产系统在丰田实施,评估其供应链,并确定哪些是增值活动,哪些不是增值活动。

Inventory Holding:库存持有

Advantages:优点

The aspect which proves to be an (Silver, E.A., D.F. Pyke, R. Peterson 1998) advantage with regards to high inventory holding is that it acts as a buffer to the company when market demands are high. If prices are expected to rise then high stocking results in capital advantage or gain. The risk of supply shortage is overcome by high inventory. Market shortage of goods is also met with by high inventory.

事实证明在高库存方面的优势在于,当市场需求高时,它可以作为公司的缓冲。如果价格预计会上涨,那么高库存会带来资本优势或收益。高库存克服了供应短缺的风险。市场上的货物短缺也受到高库存的影响。

Disadvantages:缺点

High cost warehouse management is the main disadvantage of having large inventory of finished products. There could be a possible capital loss to the business if the prices fall in the market in future. Cash is bound in carrying stocks and there is a risk of loss on account of degradation, defects and write-offs. Lack of proper management of inventory could lead to losses too. It should be noted that though inventory assists in operations, it is an asset that ties up funds i.e. working capital and the related opportunity cost.

高成本的仓库管理是拥有大量成品库存的主要缺点。如果未来市场价格下跌,企业可能会遭受资本损失。现金被限制在库存中,并且存在因退化、缺陷和注销而损失的风险。缺乏适当的库存管理也可能导致损失。应该注意的是,虽然库存有助于运营,但它是一种资产,它会占用资金,即营运资金和相关的机会成本。

Other disadvantages: 其他缺点

Stock could be stolen, lost or forgotten 存货可能被盗、丢失或遗忘

Might be dangerous to store 储存起来可能很危险

Might involve high cost to store particularly in terms of value.存储成本可能很高,特别是在价值方面。

There is a possibility of replication or duplication at several different points e.g. retail stores, hospitals, builders, merchants.在零售店、医院、建筑商、商户等多个不同点存在复制或复制的可能性。

There are additional costs such as administrative and insurance costs 还有额外的费用,如行政和保险费用

Techniques to purchase stock and manage inventory efficiently 有效采购库存和管理库存的技巧

It is vital for any (Blackburn, J.D. 1990) business organization to learn to manage inventory with efficiency thereby making possible a company to stock inventory sufficiently to meet the consumer needs. Lack of sufficient stock leads to delays and causes disrepute to the business. On the contrary, large inventory block organizational funds. A business which is primarily retail makes money only on the sale of stock and maintenance of stocks involves the following costs:

任何商业组织都必须学会高效地管理库存,从而使公司能够充分库存以满足消费者的需求。缺乏足够的库存会导致延误,并导致企业声誉受损。相反,大量库存阻碍了组织资金。以零售为主的企业仅通过销售股票和维护股票赚钱,涉及以下成本:

Charges of Interest on any loans taken to buy goods. 购买商品的任何贷款的利息费用。

Charges for storage space.存储空间费用。

Transportation costs for stock movement and for its display.库存移动及其展示的运输成本。

Cost of time involved in stock management.库存管理所涉及的时间成本。

Cost involved in stolen of damaged stocks.被盗受损库存的成本。

Payroll expenses.工资支出。

Substantial amounts of an organization’s funds could be blocked in inventory. Apt management of inventory essentially leads to high profits and lower costs.

一个组织的大量资金可能被冻结在库存中。库存的恰当管理本质上导致高利润和低成本。

Purchase the right products 购买合适的产品

Employ market research to make the identification of right products for the right market. 利用市场研究,为合适的市场确定合适的产品。

Analysis of sales charts of previous financial years. 分析上一财年的销售图表。

Identify needs of consumers and create those products to satisfy needs. 识别消费者的需求并创造满足需求的产品。

Analysis of economy forecast in the periods to come and make a determination of how market would function or react. 分析未来时期的经济预测,并确定市场将如何运作或反应。

Draw comparison between you and your competitors’ sales. 将你和竞争对手的销售额进行比较。

Make the right decisions based on experience regarding what to products to buy and at what quantity. 根据经验做出正确的决定,决定购买什么样的产品和数量。

Buying Correct Quantities 购买正确数量

In order to meet the varying market demand, it is necessary to maintain the right quantity of inventory. In the process of maintaining the right quantity of inventory care should be taken to not have overstocking of obsolete products. (Gilmore, J.H., B.J. Pine. 2000)

To do this you must:

为了满足不断变化的市场需求,有必要保持适当的库存量。在保持适当库存量的过程中,应注意不要积压过时的产品。

为此,您必须:

Have knowledge of the right product to order 了解要订购的正确产品

Order the right quantity of the product 订购正确数量的产品

Have knowledge of the right time to order the product 了解订购产品的正确时间

Have knowledge of product arrival 了解产品到货情况

Have knowledge about the right quantity of product to stock during the business cycle 了解业务周期内库存的产品数量

Have knowledge of when reorders need no submission 了解何时无需提交订单

Have knowledge of when products should not be stocked 了解产品不应存放的时间

This knowledge is acquired by analysis and experience:这些知识是通过分析和经验获得的

Ensuring suppliers have market repute and would supply products in needed quantities.

确保供应商具有市场声誉,并能提供所需数量的产品。

Making a study of lead times for the purpose of supply and delivery to make possible ordering at the apt time, or determining the delivery time for the consumers is more products have to be ordered.

为了供应和交付,研究提前期,以便在适当的时间订购,或者确定消费者的交货时间,需要订购更多的产品。

Overbuying should be avoided just to take advantage of special supplier deals.

应该避免过度购买,只是为了利用特殊的供应商交易。

Re-check buying plans weekly and amend as needed. If the stock is being sold or being utilized faster than expected, look to source more products as soon as the trend is identified and in existence.

Make a note of required stock levels (minimum, maximum and at the point to re-order).

每周重新检查购买计划,并根据需要进行修改。如果库存的销售或使用速度比预期快,那么一旦发现趋势并存在,就寻找更多的产品。记录所需库存水平(最低、最高和重新订购时)。

Success of Inventory Control:库存控制成功

The regular and periodic (Stalk, G., T.H. Hout. 2003) evaluations of key performance indicators in companies help determine the success of an inventory system. The basic group of indicators reveals how well the inventory system fulfills the business needs and does it exceed the customer expectations. The inventory system should have the capability of accounting for that exists at the finished goods inventory with the inclusion of what was manufactured in the latest production cycle. This process makes it possible to bring forward units for consumer orders in at the right time without delays and help companies shorten the lead-time and thus building repute in the process.

对公司关键绩效指标的定期和定期评估有助于确定库存系统的成功。基本指标组显示了库存系统满足业务需求的程度以及是否超出了客户的期望。库存系统应具有核算产成品库存中存在的库存的能力,包括最新生产周期中制造的产品。这一过程可以在正确的时间为消费者订单提供单位,而不会延迟,并帮助公司缩短交付时间,从而在过程中建立声誉。

An efficient system makes it possible to maintain a good balance between the stock that is in possession and the stock that is required to operate the business efficiently.

一个有效的系统可以在拥有的库存和有效经营业务所需的库存之间保持良好的平衡。

Global Supply Chain Management:全球供应链管理

For many business (De Geus, A., (1998) organizations, Global Supply Chain Management has become increasing important as there has been an increase in offshore sourcing and globalization. As global supply chain management involves many countries thereby the issues or difficulties to be tackled are many too. Primarily the overall costs need to be considered. Though labor cost could be minimal, cost of space, tariffs and other costs needs to considered with doing business abroad. The exchange (Drucker, P. (1988), rate too needs to be factored. The company’s lead-time could positively or negatively affect depending on the productivity of the employees overseas and the shipping time involved. There could be time lags on account of custom clearance time and other governmental red tape. (Gersick, C. J. G. (1991). Supplier selection is also another important aspect of global supply chain management. Extensive research should be carried out by the company to help make the right choice. Logistical issues such as deciding the number of plants and their locations to surface and have to be worked out carefully. (Romanelli, E. and Tushman, M. L. (I994)

对于许多企业来说,随着离岸外包和全球化的增加,全球供应链管理变得越来越重要。由于全球供应链管理涉及许多国家,因此需要解决的问题或困难也很多。首先需要考虑整体成本。尽管劳动力成本可能很低,但在国外开展业务时,需要考虑空间成本、关税和其他成本。汇率也需要考虑。公司的交货期可能会对海外员工的生产力和所涉及的运输时间产生积极或消极的影响。由于清关时间和其他政府繁文缛节,可能会有时间延迟。供应商选择也是全球供应链管理的另一个重要方面。公司应进行广泛的研究,以帮助做出正确的选择。后勤问题,如决定工厂数量及其浮出水面的位置,必须仔细解决。

Assembler-supplier relationships in the global auto industry 全球汽车行业的装配商与供应商关系

For the last two decades, there has been a change in the relationship between assemblers and suppliers. Initially there has been a shift from supply of individual components to supply of complete function such as “corners”, systems, modules or sub-assemblies.

(Sadler, D. (1998) a supplier who is first-tier assembles parts and makes a supply of them as complete units (such as dashboards, rear axle assemblies, body panels and seats). Operations earlier carried out in-house by the assembler, such as the manufacture of seats and exhaust systems, are moved on to the first-tier supplier. Second, component producers have taken an further role in the creating design of components and systems (Humphrey, J. and M. Salerno (2000) First-tier component producers assert more involvement with their consumers and have transited to providing ‘black box’ parts or systems. While the assembler gives overall performance specifications and information about the interface with the remaining aspect of the car, the supplier designs a solution using its own technology, often taking in a basic design to the customer’s specific requirements.3 This shift has facilitated car assemblers to transfer R & D costs to component manufacturers and to take advantage from the specialized technological skills of these producers.

在过去二十年中,装配商和供应商之间的关系发生了变化。最初,已从供应单个部件转向供应完整功能,如“角落”、系统、模块或子组件。一家第一级供应商,负责组装零件,并将其作为完整的部件(如仪表板、后轴总成、车身面板和座椅)供应。早些时候由组装商在内部进行的操作,如座椅和排气系统的制造,都转移到了第一级供应商。第二,组件生产商在组件和系统的创建设计中发挥了更大的作用。第一级组件生产商主张更多地参与其消费者,并已过渡到提供“黑箱”零件或系统。虽然装配商给出了总体性能规格和与汽车其余方面的接口信息,但供应商使用自己的技术设计解决方案,通常根据客户的具体要求进行基本设计。3这种转变促使汽车装配商将研发成本转移到零部件制造商,并利用这些制造商的专业技术技能。

Conclusion 结论

As supply chains have moved from a cost focus to a customer focus and now currently to a strategic focus, the need to think strategically about the supply chain has never been more important. The success of a strategy is only as good as the company’s ability to fully and properly execute it. A great supply chain strategy, linked with operational excellence, can provide success for not only the company in question but also its partners and customers.

随着供应链从以成本为中心转向以客户为中心,目前又转向以战略为中心,对供应链进行战略思考的必要性从未如此重要。一项战略的成功与否取决于公司是否有能力充分、恰当地执行它。一个伟大的供应链战略,与卓越的运营相联系,不仅可以为相关公司,也可以为其合作伙伴和客户带来成功。

Methodology:方法论

This chapter will essentially focus on the method employed for the conduct of research and analysis. The reasons governing the techniques chosen would be furnished. Furthermore, the chosen method of analysis of data compiled and the ethical consideration therein would be discussed.

本章主要关注研究和分析所采用的方法。将提供控制所选技术的原因。此外,还将讨论所选择的数据分析方法以及其中的伦理考虑。

Primary Research:主要研究

Ethical Considerations:道德考量

The researcher is of the conviction that no research should be carried out without attention being paid to the implications which are of ethical nature. On ethical grounds, the researcher presented in all clarity to the participants or volunteers for this research study that the research was purely for academic reasons and the data compiled and analyzed would be utilized for the purpose of Academic projects and would not be in any manner shared with any other individuals other than Academicians evaluating the research conducted nor would the data collected be employed for commercial usage. The researcher provided this indemnification and hence the participants agreed to volunteer vital information regarding Kapoor Automobile’s policies of Inventory holding and Global supply chain management.

研究者坚信,在进行研究时,不应忽视伦理性质的影响。基于伦理的理由,研究人员向本研究的参与者或志愿者明确表示,该研究纯粹出于学术原因,所收集和分析的数据将用于学术项目,不会以任何方式与任何其他个人共享,而非评估所进行研究的院士,也不会将收集的数据用于商业用途。研究人员提供了这一赔偿,因此参与者同意自愿提供有关卡普尔汽车库存持有和全球供应链管理政策的重要信息。

Furthermore the participants were informed of the fact that no participation fee would be levied or charged.

此外,与会者还被告知,不会收取任何参与费。

Face to Face Interviews:面对面访谈

Face to face interviews were conducted with the C.E.O. of Kapoor Automobiles (India) and the Board of Directors of the company to gain an understanding into the overall aspects of the functioning of the organization and to also gain information about their modes of Inventory control in their Global Supply Chain Management activities. Information about this was provided it in depth and the research succeeded in getting a clear practical picture of their operations. The researcher failed to acquire figurative data relating to inventory control as the C.E.O and the Board of Directors expressed confidentiality issues. The interviews too were conducted in an informal manner as they the participants (C.E.O and Board of Directors) insisted on anonymity and the researcher assured them of the same.

与卡普尔汽车首席执行官和公司董事会进行了面对面访谈,以了解组织运作的整体方面,并了解其全球供应链管理活动中的库存控制模式。关于这一点的信息被深入地提供了,研究成功地对他们的行动有了清晰的实际情况。由于首席执行官和董事会表示存在保密问题,研究人员未能获得与库存控制相关的形象数据。采访也是以非正式的方式进行的,因为参与者(首席执行官和董事会)坚持匿名,研究人员也向他们保证了这一点。

For gaining an understanding of the production process and actual physical inventory control process, rubber technicians and warehouse supervisor of Kapoor Automobiles (India) were interviewed and productive insight was gained by the researcher.

为了了解生产过程和实际实际库存控制过程,采访了卡普尔汽车(印度)的橡胶技术人员和仓库主管,研究人员获得了生产洞察力。

Time and Access:时间和访问

Limitations emerged in the form of lack of time and access in the case of certain Board of Directors of Kapoor Automobiles. Of the 8 Board of directors, 2 of them could not be accessed as they were overseas to conduct negotiations of Kapoor Automobiles (India) and hence they could not be interviewed. Some of the available Board of Directors could not spare sufficient time of the interviews as they had to attend to the day to day management affairs of the organizations. Though the time they made available was limited, their input were undoubted valuable.

在卡普尔汽车公司的某些董事会中,由于缺乏时间和访问权限,出现了限制。在8名董事会中,有2名董事因在海外与卡普尔汽车进行谈判而无法联系,因此无法接受采访。一些可用的董事会无法抽出足够的时间进行面试,因为他们必须处理组织的日常管理事务。尽管他们提供的时间有限,但他们的投入无疑是有价值的。

The C.E.O. expressed inability to even provide approximations of figurative data citing confidentiality issued and hence the researcher failed to have access to any figurative data whatsoever.

首席执行官表示,甚至无法提供形象数据的近似值,理由是发布了保密信息,因此研究人员无法获得任何形象数据。

Secondary Research:次要研究

The techniques of secondary research employed by the researcher were essentially gaining vital data from the online library provided by Cardiff Business School. This library of the Cardiff Business School was of immense utility as all the theories relating to Inventory Control and Global Supply Chain Management were available in abundance and facilitated a process of ease in understanding and compiling the much required theories and data. The search engines of Mintel and Ebsco proved to be of immense use to the researcher.

研究人员采用的二级研究技术基本上是从卡迪夫商学院提供的在线图书馆获取重要数据。卡迪夫商学院的这个图书馆具有巨大的实用性,因为与库存控制和全球供应链管理相关的所有理论都非常丰富,有助于轻松理解和汇编所需的理论和数据。Mintel和Ebsco的搜索引擎被证明对研究人员非常有用。

Besides the above mentioned source, the researcher referred to several books written by experts in the field of Inventory control and Global Supply Chain Management to acquire multiple perspectives on the area of research and analysis. The information gained was significant and hence employed by the researcher in his research study.

除上述来源外,研究人员还参考了库存控制和全球供应链管理领域专家撰写的几本书,以获得研究和分析领域的多个视角。获得的信息非常重要,因此研究人员在其研究中使用了这些信息。

Findings and Analysis:发现和分析

Introduction:简介

Employing the primary research techniques, the researcher learnt through face to face interviews of the C.E.O and Board of Directors of Kapoor Automobiles (India) that the organization being medium-sized, financially they are not in a position to have high levels of inventory to meet unforeseen demands of the consumers in the Global Supply Chain Management process. Kapoor Automobiles (India) initially commenced as a very small business outfit carrying out its production, stocking and distribution activities from a very small workshop. Kapoor Automobiles (India) grew successfully over a period of time and now possess a large production and warehousing unit in comparison to what they had when the business commenced and this is owing to the fact that business leaders at Kapoor Automobiles (India) formulate the apt strategy to meet demand of consumers spread across the continents of Asia, Europe and the Middle East. Financial constraints necessitate Kapoor Automobiles (India) to follow the Just-in-time inventory management process.

利用主要研究技术,研究人员通过对卡普尔汽车公司首席执行官和董事会的面对面访谈了解到,该公司规模中等,在财务上无法拥有高水平的库存,以满足全球供应链管理过程中消费者的意外需求。卡普尔汽车最初是一家非常小的企业,在一个非常小的车间开展生产、库存和分销活动。卡普尔汽车公司在一段时间内成功发展,与业务开始时相比,现在拥有一个大型的生产和仓储部门,这是因为卡普尔汽车公司的商业领袖制定了适当的战略,以满足亚洲、欧洲和中东各大洲消费者的需求。财务约束要求卡普尔汽车遵循准时库存管理流程。

Just-in-time (JIT) could be defined as a strategy of inventory management. This methodology focuses on bringing about an improvement in the firm’s return on investment by bring down or reducing the in-process inventory and related carrying costs. Just-In-Time production method is also termed as Toyota Production System. In order to fulfill objectives of Just-In-Time, this inventory management method is reliant on Kanban or signals emerging between different points in the link, which indicate the production department as to when the next batch should be produced.

准时制可以定义为库存管理的一种策略。该方法侧重于通过降低或减少在制品库存和相关账面成本来提高公司的投资回报。准时生产法也称为丰田生产系统。为了实现准时制的目标,这种库存管理方法依赖于看板或链接中不同点之间出现的信号,这些信号指示生产部门何时生产下一批产品。

Initially, Kapoor Automobiles (India) was following this method on account of financial constraints which did not permit holding large inventory but now Kapoor Automobiles (India) prefers this method as the market trend is changing in continuity on account of new technological developments at regular and short intervals and this required constant change in product and the production methods and the other obvious reason as stated by Kapoor Automobiles (India) is the fact that they are yet a medium sized enterprise and would not be in a position to have large inventory.

卡普尔汽车开始采用这种方法是因为财务限制,不允许持有大量库存,但现在卡普尔汽车更倾向于采用这种方法,因为由于定期和短时间内的新技术发展,市场趋势不断变化,这需要产品和生产方法的不断变化,卡普尔汽车指出的明显原因是,他们仍然是一家中型企业,无法拥有大量库存。

They further stated that large inventory for the Global Supply Chain Management process could lead to financial losses as the inventory could go obsolete as the automobile industry is a progressive and booming industry and there is a requirement of constant modification in the spare parts or components utilized for the manufacture of automobiles.

他们进一步表示,全球供应链管理流程的大量库存可能会导致财务损失,因为汽车行业是一个进步和蓬勃发展的行业,需要不断修改用于制造汽车的零部件或部件,因此库存可能会过时。

Conclusively, Kapoor Automobiles (India) have stated that Just-In-Time inventory management system helps them reduce the in-process inventory costs and other related costs and hence is the most preferred mode of inventory management. They further state that their organization is in a state of growth in continuity and they objective aim at converting Kapoor Automobiles (India) which is currently a medium sized organization into a large sized organization and when Kapoor Automobiles (India) attains this objective they would continue to function utilizing Just-In-time inventory management system to meet the demands of their clients in the Global Chain as the product features and demands related to it are changing continuously and maintaini.

最后,卡普尔汽车表示,实时库存管理系统有助于他们降低在制品库存成本和其他相关成本,因此是最优选的库存管理模式。他们进一步表示,他们的组织处于持续增长的状态,他们的目标是将卡普尔汽车公司目前是一家中型组织)转变为大型组织,当卡普尔汽实现这一目标时,他们将继续利用及时库存管理系统来满足他们的需求全球链中的客户,因为与之相关的产品特性和需求不断变化。本站提供各国各专业Research Paper代写或指导服务,如有需要可咨询本平台。