代写需求

dissertation题目:看附件说明

dissertation语种:英文

您的研究方向:管理

是否有数据处理要求:是

您的国家:英国

您的学校背景:一般

要求字数:无字数要求,分析到位就好

dissertation用途:硕士课留学dissertation程dissertation Master Assignment

是否需要盲审(博士或硕士生有这个需要):否

补充要求和说明:1.需要用到PROJECT 2003做一些数据处理

2.按照REPORT格式

对于题目的疑问,老师给予的解答

1Q: For this assignment, is there any word limit?

1A: No, but you should cover your analysis sufficiently in a concise manner.

2Q: "... should we use figures 1 and 2 to establish the approximate depths and

lengths of the constructions?"

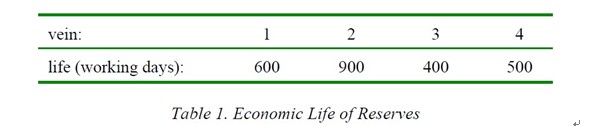

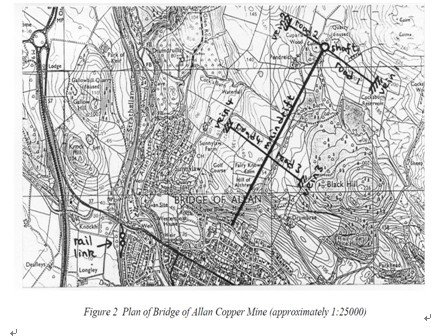

2A: Yes, and please note that Figure 1 should be used to determine the vertical

dimension and Figure 2 the horizontal ones. Don't use Figure 1 to calculate the

horizontal dimensions since they are not to scale.

3Q: the scale on figure 2 is 1:25000, is this 1cm: 25000m?

3A: No, 1:25000 means 1cm on the map is 25000cm in reality.

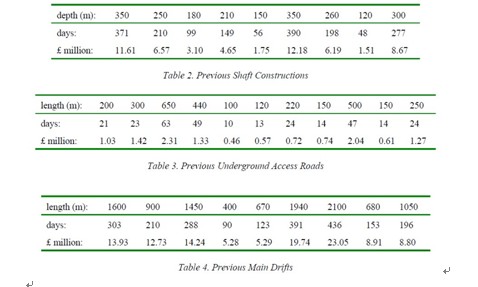

4Q: using the statistics of previous mining of main drift for example (table 4),

should we average them all or add them together?

4A: You are right that the information is provided to help you estimate better. But

is averaging the given data the best way to use the info?

5Q: "after finishing bore-hole 2 can we directly dig the main drift to the bottom of

bore-hole 2 or we need also to wait for the previous drift to reach the bottom of

bore-hole 1 first?"

5A: There is only one drift so you can only get to the second part after you finish

#p#分页标题#e#the first.

6Q: following the above question, "Do we need to also wait until the bore-holes

made for Vein 3 & 4 are finished ?"

6A: The sequence is likely to be: bore hole first, then road, then mining.

7Q: for shaft construction "do we also need to wait until the drift reach the bottom

of boreholes 5 & 6 also?"

7A: If there is no dependency specified, you don not need to plan for it.

8Q: Does the project run 7 days a week or 5 days a week? Because for operations

it is given that 5 days a week, but nothing is mentioned for project phase.

8A: Make whatever assumption you feel necessary here.

9Q: once the main drift reach the intersection of roads 3 &4, can we then start

working on roads 3 & 4 and on the same time continuing the main drift toward bottom

of bore hole 3 ? in other words, can we [do] parallel work packages for the drift

and the roads ?

9A: Yes you can as far as you respect the specified dependencies.

The report marking criteria will be:

1. The logic of the basic project plan, both in terms of scheduling and finance;

2. The justification of your conclusions by reasoning and calculations;

3. The overall quality of presentation with the help of tables and graphs where appropriate.#p#分页标题#e#

Bridge of Allan Copper Mine

Introduction

Copper and silver were mined at various locations in the Ochil Hills until 1807. Evidence of the mining activity can be seen in the woods at the back of Bridge of Allan, including the prominent, blocked entrance in Mine Wood. The mines have been long abandoned as uneconomic but recent increases in commodity prices have caused various mining prospects to be reassessed. The Airthrey Mining Company (AMC) was formed two years ago and has already undertaken much prospecting and proven that there are small but rich reserves of copper well worth extracting. Considerable public relations work has persuaded the local communities of the value of the project to Scotland’s strategic economic development and outline planning permission has been agreed. AMC believe that there should be sufficient reserves for a long term operation and many experts believe that the high copper prices should continue for many years. However, AMC want to establish the first phase of the mine quickly so that the mine can take full advantage of current market conditions.

AMC have already undertaken many studies of the proposed mine and extracts from the reports are provided:

geology

company strategy

mine development

mine operations

purchasing

surface services

personnel

Task

You have been asked as a project management consultant to help AMC assess whether the Bridge of Allan copper mine is financially viable and recommend a project plan. You should produce a report for

the AMC Board of Directors in time for its next meeting. The report should provide:

• a plan illustrating the logic of the project and identifying project activities, their durations and key milestone dates;#p#分页标题#e#

• an assessment of the project’s financial viability, assuming the best estimates for the price of copper;

• an exploration of the effects of changing copper price: how dependent is the project’s viability on these assumptions?

• justify your analysis with supporting evidence where appropriate;

• A rival mining company from Northern England has made an offer to acquire the mining rights from AMC for a total sum of £2.95million. This offer is due to expire by the end of August 2010. Advise the AMC Board whether it is worth taking up this offer.

Sensible approximations should be adopted where appropriate. The report should be written using the standard guidelines. Include a section summarizing possible further studies that you would recommend to provide a more complete assessment.

Geology

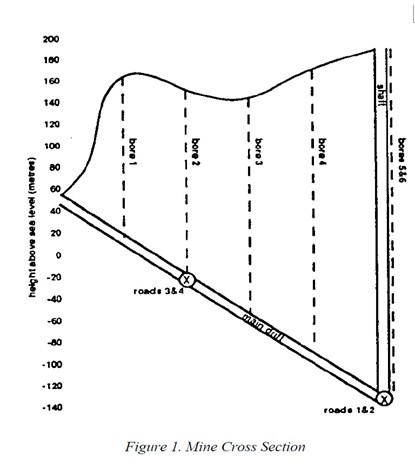

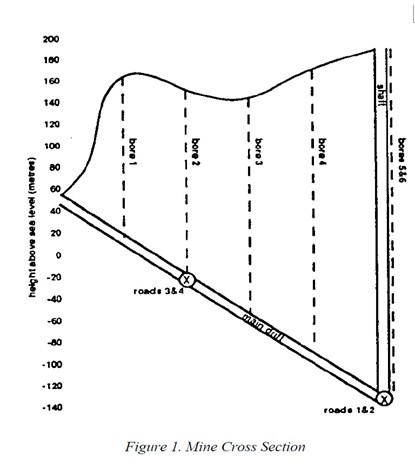

While the general geology has been proven and there is every confidence that the copper reserves are as claimed, the precise geology is not known. A more detailed geological knowledge is needed to provide information about the nature of the ground being tunnelled through and the exact location of the copper veins. More boreholes need to be sunk to provide cores of the geological strata from key locations, see Figure 1. Ten boreholes are required: four associated with the drift, two with the shaft and one with each vein. The mine cross section and plan indicate the approximate locations of the shaft, drift, roads and boreholes. There is no need to complete all the boreholes before mining begins, but each borehole must be finished before the immediately previous stage of the associated mining development can start. For example bore 1 must be finished before the main drift is started but the drift may then progress to the bottom of bore 1, even though bore 2 etc. may not be completed. However, tunnelling the drift can not continue to the intersection with roads 3 and 4 until bore 2 has been sunk. Similarly the sinking the shaft can not begin until bores 5 and 6 have been completed.

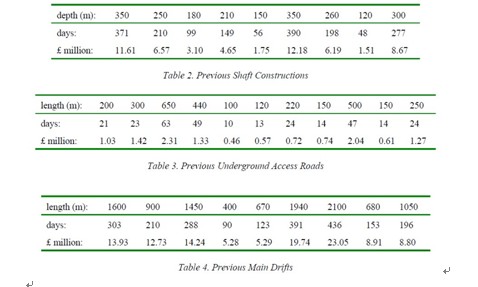

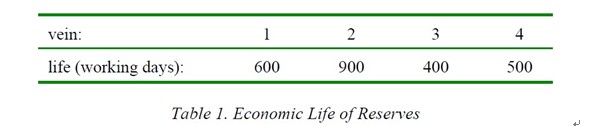

The boreholes will be drilled using a lightweight drilling rig which is attached to a tractor. This rig can thus cross rough country and does not need any specially built roads. The rig is fairly primitive but it is relatively cheap. A specialist firm hires out the rig at a fixed cost of £100 000 plus £1000 per day for the equipment and support team. Extensive experience indicates that a drilling rate of 4m per day should be achieved. It is hoped that only one rig will be used though more might be made available if really necessary. It has been estimated that the economic life of each of the four veins to be worked in the proposed development are:#p#分页标题#e#

Company Strategy

The proposed development should establish the expensive key infrastructure: surface transport facilities, shaft and underground drift. This development will also involve the driving of four underground roadways to access four veins of copper ore for extraction. It is argued that even if the first phase of the development留学生dissertation (working veins 1-4) is not quite viable (using the company’s standard 20% p.a. discount rate) future phases with extended roadways to access new veins should be very profitable. However, there is no detailed assessment of the geology of any additional veins at present.

Mine Development

The main drift will provide access from Bridge of Allan, at an entrance opposite the tennis courts, sloping down to intersect a shaft sunk from Cuparlaw Wood, see Figure 2. The underground access roads (1-4) will link the drift, shaft and the four copper veins. A mixture of conveyor belts and underground trains will be used in the drift and roadways to transport men, materials and the copper ore. The roads can be driven as soon as access is possible, either via the shaft or drift.

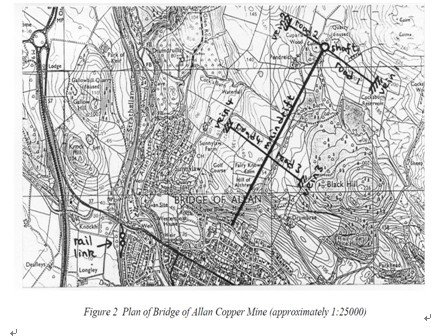

Data describing development work at other mines have been collected for the sinking of the shafts and driving main drifts and the smaller access roads, such as roads 1-4. The costs include all labor, machines and essential materials, such as concrete lining for the shaft, but exclude fittings, see separate section below.

There is the possibility of using a new shaft sinking machine which has had considerable success in other mining developments. The new machine has proven a reliable rate of 1.5 metres per day but the costs, including all the skilled support required and essential materials, are £70000 per day. While this might be an option, the great expense raises a question on its economic justification.

#p#分页标题#e#

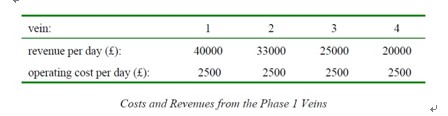

Mine Operation and revenue

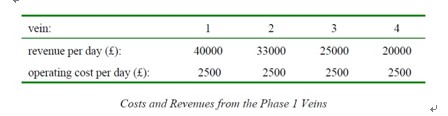

No removal of ore is allowed until both the shaft and the drift have been completed, providing the ventilation needed for the larger workforce employed in extraction. Estimates have been made of the operating costs of the mine and the daily revenue from the veins once ore extraction begins:

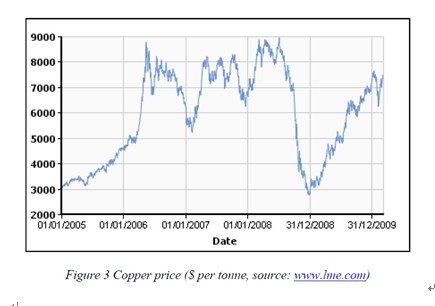

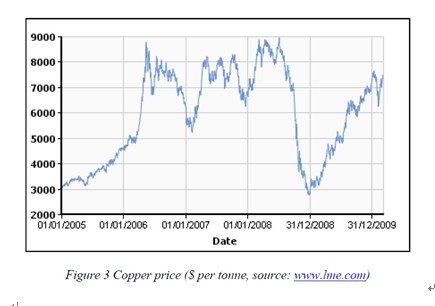

Various shift patterns have been considered but the mine will work a 5 day week for 50 weeks per year, with the weekends being reserved for maintenance and safety checks. The revenue has been estimated based on a conservative copper price of $5500 per tonne: the price of ore can be assumed to be proportionate to the price of copper. It is expected that the copper price will remain relatively high for the next few years, though price fluctuations are often unpredictable (see Figure 3).

Purchasing

A number of specialized items of equipment have to be procured with long lead times:

Surface Conveyor

In addition to the preparation and installation costs included in “Ore Transport and Storage”, the purchase cost of the components will be £700000. 3 months should be allowed for delivery.

Shaft and Roadway Fittings

Numerous fittings will be required, such as the cage for the shaft, ventilation piping, pumps, communications, lighting, conveyor structure and belts. The total cost will be about £5.5 million and 3 months should be allowed for delivery. No work can begin on the shaft or drift until the fittings are available.

Underground Railway

Track, signalling, locomotives and wagons will be required at a cost of £1.9 million and with a delivery time of 4 months.

Surface Services

While most of the activity and expense is involved with the underground development, there are a number of vital surface facilities necessary for the mine's operation:#p#分页标题#e#

Access Roads

The road to the drift entrance will have to be english essay upgraded (cost= £100,000 and time= 4 weeks) before any work on the drift can begin. Similarly the road to Cuparlaw Wood will be upgraded (cost= £300000 and time = 7 weeks).

Cuparlaw Buildings

The main surface buildings will be located at Cuparlaw Wood, minimising the impact of AMC's development on Bridge of Allan. A workshop (£500,000 and 12 weeks), office (£400,000 and 10 weeks), changing rooms (£300,000 and 10 weeks) and canteen (£150,000 and 8 weeks) will be built.

Ore Transport and Storage

The copper ore will emerge from the drift and then be taken by conveyor (£200,000 and 8 weeks for its installation) along the back of Bridge of Allan and then directly across Blairforkie Drive to bunkers (£600,000 and 4 weeks for their construction) on the site presently occupied by the garden centre next to the station. A railway siding (£500,000 and 6 weeks) will be built where railway wagons will be loaded for transport to market. Before any work on the railway facilities, a detailed agreement has to be made with ScotRail. 4 months should be allowed for discussions for this agreement.

Personnel

While the specialist manpower required for the development of the mine will be supplied on a contract basis, a permanent workforce will be needed for the routine operation of the mine: the extraction and transport of the ore. Recruitment should begin 6 months before the start of any ore extraction.

Planning permission and start date

Outline planning permission has already been agreed. Once the board of AMC confirm the project, work could start as soon as 1 June 2010.

Project management and mine supervision

It is estimated the cost of project management during the development of the mine and the cost of supervision once the mine is operational will be about £3000 per working day.